After the years of development of the charcoal briquette machine line, the properties of the machine grew with the demands of the customers. The large-scale charcoal machine line is the perfect proof that Sunrise Machinery Company puts the customer first place. The large-scale charcoal briquette-making line meets the customers’ special needs according to the machines’ improvements. The manufacturer can customize the production line to provide the best purchase experience for the customers.

What is a large-scale charcoal production line?

Accordingly, one can guess the biggest characteristic of this charcoal production line is its capacity through its name. Since most of the raw materials are biomass or agricultural waste materials, the accessibility of the material resources determines the huge capacity of the production line. There is no avoiding the development of large-scale charcoal production lines. Therefore, the volume of the raw materials has to be huge to earn more profits for the business owners. The large-scale charcoal production line is the consequent result of the development of the charcoal production line.

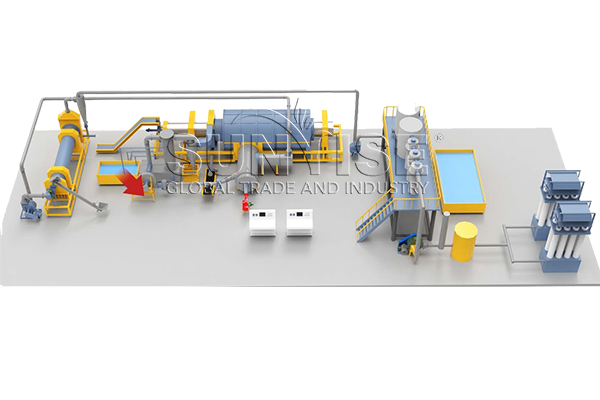

As a large-scale charcoal production line from the Sunrise Machinery Company, it usually has the characteristics of a high degree of automation, high production efficiency, and stable product quality. Above all the merits can help the production line to meet the demands of mass production and higher requirements. At the same time, the techniques of the machine line evolve with technologies. Increasing production lines adopt advanced machines and technologies to accelerate production efficiency and save the cost of energy.

What are the components of the large-scale charcoal machine line?

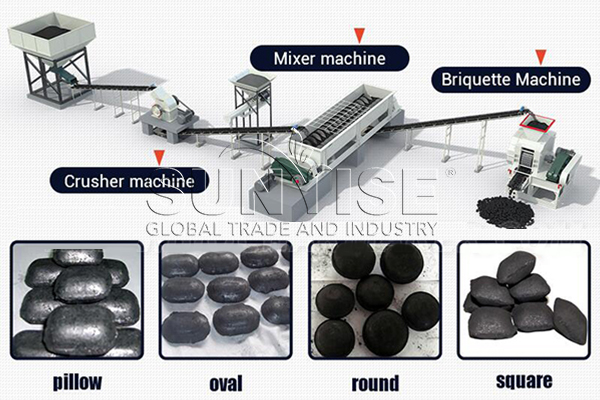

Like other kinds of charcoal production lines, the basic functions of a charcoal production line are the same. What is different from the other kinds of briquette machine lines is the detailed parameters of the machines. In order to achieve the goal of high capacity, the machines have to have the ability to deal with a great amount of raw materials.

Crushing Equipment

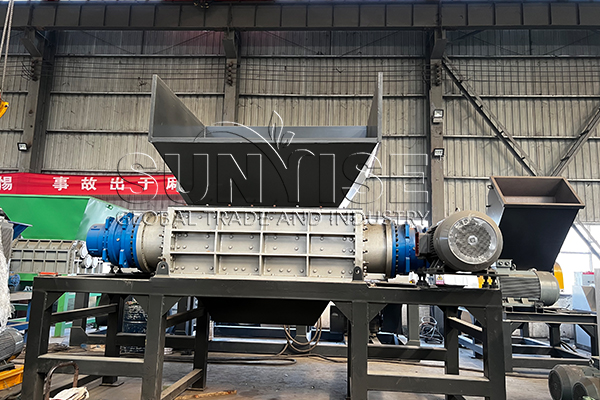

In the process of charcoal production, two procedures require the utilization of the crushing equipment. One is the first step of the whole production line, and the other is the charcoal bulks that get out of the carbonization furnace.

For one thing, the main purpose of the crushing machine is to shape the materials into suitable shapes to ease further processing. The double-shaft shredder machine has the ability to dispose of several raw materials into debris with strong strength. As for the grinding machine for the charcoal bulks, the Raymond mill machine or industrial pulverizer is the perfect choice of grinding machine. These machines can not only cut the raw materials into suitable sizes but also allow the operator to add additives to the charcoal powder to increase the quality of the final products.

Briquette Machine

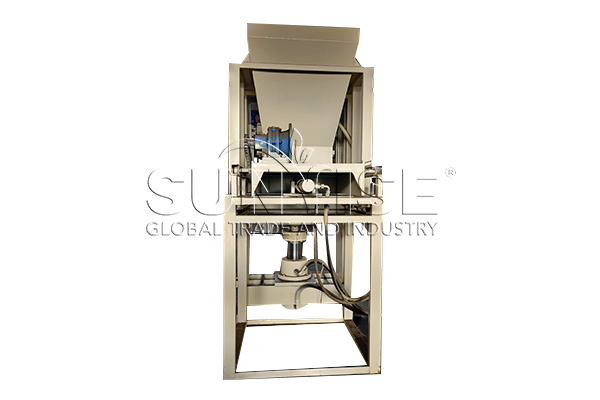

After the grinding machine, the charcoal powder gets in the briquette pressing machine for shaping. To comply with the high capacity of other machines, the customers would usually choose the rotary tablet press machine and roller press briquette machine. Moreover, these machines use an automatic system to control the working system. Therefore, the working efficiency of the machine has a strong guarantee.

What advantages does the large-scale charcoal line contain?

The Large-scale charcoal briquette-making line specializes in the treatment of large amounts of raw materials. The combination of the production line contains the professional and thoughtful thinking of the designers of Sunrise Machinery Company. There are several unique advantages of the production line to attract more customers.

Efficient Production

More products in a shorter timeLarge-scale carbonization production lines usually have advanced process technology and automated control systems. The automatic working method achieves efficient production processes and improves production efficiency. Large carbonization production lines generally have large production capacity, which can meet the needs of large-scale production and reduce production costs.

Precise Control

Accurateness makes adequate productsThe production line can precisely control the temperature, oxygen content, pressure, and other parameters. Not to mention guarantee the production to meet the requirements of the customers. As a result of precise control and efficient production, large carbonization production lines can produce high-quality carbide materials with stable product quality.

Automatic Operation

Less operation, higher capacityLarge carbonization production lines usually have automated control systems. It can realize the automated operation of the production process, reduce manual intervention, and improve production efficiency and product quality. Some modern large-scale carbonization production lines adopt energy-saving and environmentally friendly designs and processes, which can reduce energy consumption and waste emissions, and reduce the impact on the environment.

What is the cost of building a large-scale charcoal briquette-making line?

As the large-scale charcoal production line consists of many high-capacity machines, the price of the production line can be higher than the normal charcoal production line. The normal price of the large-scale charcoal production line is higher than $80,000, and if the customers have some specific requirements for the production line, the price range can expand to $300,000. Therefore, the customer needs to have a clear idea of the ideal production line to purchase the suitable machine.

Sunrise Machinery Company can provide high-quality and high-capacity equipment for customers. The company also has the specialists to design the structure of the factory to realize reasonable use of space. If you would like to learn more about the machine and large-scale charcoal production line, please leave a message about your requirements. The company is looking forward to your inquiry.