With the awakening of environmental awareness, people put more attention to searching for sustainable and environmental materials. In order to produce energy while protecting the environment, the biomass charcoal production line is one of the perfect choices. Sawdust is one of the newest renewable sources that producers are fond of. The sawdust charcoal briquette machine line can convert the sawdust into charcoal briquette to add more value to the final products. The machines in the production line offer the technical assistance to bring out the potential of the sawdust material. Sawdust charcoal has a wide application in energy supply, so biomass charcoal contains a promising future.

What is a sawdust briquette machine line?

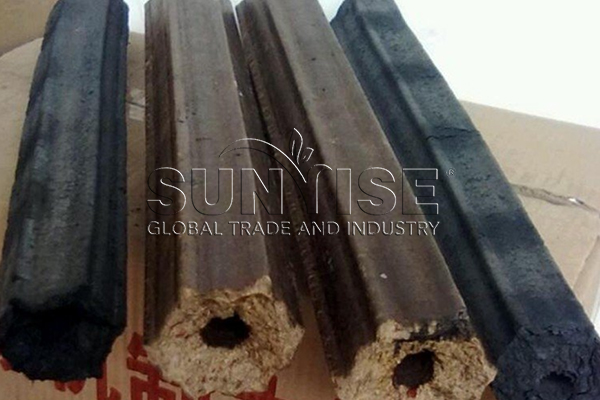

The sawdust briquette machine line uses the sawdust as the raw material to produce the charcoal briquette. The sawdust is the by-product of wood processing. Whereas after the carbonization process, sawdust charcoal can become biomass charcoal. With high organic matter content and excellent combustion performance as its traits. All things considered with wide application value. The components of the sawdust briquette machine line are the cutter machine, the dryer machine, the carbonization furnace, the grinding machine, the briquette pressing machine, and the packing machine. Eventually, with all these machines, agricultural waste, and sawdust, can transform into renewable energy.

The advantage of the sawdust carbonization production line is that it can make full use of the byproduct sawdust in the wood processing process. In addition, converts the biomass materials into valuable biomass charcoal. The final products have the characteristics of environmental protection and sustainability. At the same time, as a new type of energy and material, biochar has a wide range of application prospects and has important application value in agriculture, industry, and energy.

How does the production line produce the sawdust charcoal?

To make the charcoal bulk, the machine line has to prepare several processing machines to realize the requirements of the final products. There are similar processing steps to the other kinds of materials, but the biggest difference is the crushing process. Unlike other materials, the size of the sawdust is rather small, so the sawdust needs a more delicate machine to shape its size during the preparation phase.

What are the uses of the sawdust charcoal briquette?

The demand for energy resources is inevitable. No matter whether it is daily life or industrial production work, the utilization of charcoal seems common. Sawdust charcoal can be applied to diverse fields to fulfill different energy requirements.

Soil Amendment

Biomass charcoal is a kind of high-quality soil amendment. Adding to the soil can improve soil structure, increase soil fertility, and improve soil water and fertilizer retention ability. What’s more, it is conducive to plant growth. The nourishment for the plant completes the cycle of environmental protection, which is a good way to realize sustainable development.

Barbecue and Heating

Biomass charcoal is the most common fuel for barbecue and heating, which has the characteristics of high heat generation, stable combustion, and less impact on the environment. The utilization in the daily life can also bring the profits to the owners. Therefore, the transformation of biomass becoming charcoal products is a promising business for the future.

Industrial Application

Biomass charcoal can occupy the position of environmentally friendly adsorbent for wastewater treatment, waste gas treatment, and environmental protection equipment in the petrochemical industry. In order to absorb the wastewater and air, the industry would require a huge amount of charcoal products. The sources of the raw materials can be wide, so the conditions of the products guarantee the sound development of the industry.

Why does the machine line take sawdust as the material?

What would a sawdust charcoal briquette machine line will cost?

In order to have an accurate number of the price of the charcoal production line, the customer has to have a clear view of the factors that influence the price of the machine line. Normally the middle-scale production line costs $10,000-$30,000. With a larger scale, the price may be higher. Therefore, the customer should learn the capacity of the factory before deciding on the purchase.

A suitable design may help to reduce the cost of the production line. Sunrise Machinery Company is not only a machine producer, with rich experience, the company can offer you the most suitable design to bring out the best performance of the production line. With the great reputation in the industry, the machines from this company contain high-quality and reasonable prices. If the customer would like to learn more professional details about the machine and production line, please leave the request through the e-mail address. The customer service staff will answer back as soon as possible.