After many years of development, the carbonization furnace experiences several versions to come to the stage of the continuous carbonization furnace. The equipment is capable of a continuous carbonization process. The structure of the continuous carbonization furnace is different from other carbonization furnaces. To improve the quality of the final product, the equipment has a rather high standard of raw materials. The continuous carbonization furnace is suitable for large-scale production and high-efficiency needs. The unique function makes the machine necessary for the charcoal production line.

What is a continuous carbonization furnace?

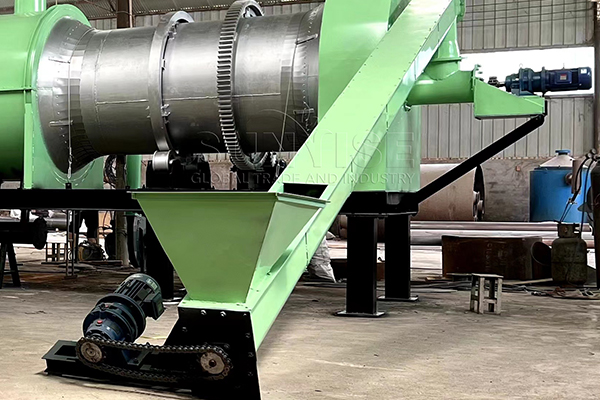

A continuous carbonization furnace is an equipment for carbonizing materials, with the characteristic of working continuously. There are two types of continuous carbonization furnaces, one is the one-story furnace and the other is the two-story furnace. The biggest difference between these two machines is the location of the inlet and outlet. The inlet and outlet of the single-layer machine are at both ends, and the inlet and outlet of a double-layer furnace are at one end. The water-cooling part of both machines is set at the outlet. The reasonable design is a summary of the whole development of this machine and is also the state of the art.

The equipment carbonizing has an important position in large-scale and efficient production, especially suitable for continuous production lines and automatic production. As a machine that coheres to the wisdom of people and the development of technology, the continuous carbonization furnace can provide the best user experience for the customers.

What requirements does the machine have for the raw materials?

Unlike other carbonization furnaces, the continuous carbonization furnace has rather strict requirements for materials to get into the carbonization chamber. The continuous carbonization furnace can take many biomass materials as raw materials to proceed with the carbonizing process. However, to improve the quality of final products and the efficiency of the process, the machine has some restrictions for the raw materials. Therefore, the raw materials need several methods of treatment before getting into the carbonization furnace.

The feed-in materials of the charring machine have moisture requirements that are less than 15%. As for other parameters, the requirement of granularity is less than 2cm, and the best size is 0.8cm. The reason why the continuous carbonization furnace has such strict requests is because these factors affect the outcome of carbonizing and process control.

The moisture means the water content of raw materials. High water content may lead to incomplete carbonization, so the quality of the final products may be lower. However, the low humidity causes the problem of over-carbonization, which also influences the final product. As for the granularity, the size of the raw material affects the process of carbonization in the same. Larger sizes may lead to incomplete carbonization, and smaller sizes may stack in the conveyor system.

What is the working process of the continuous carbonization furnace?

The working process of the continuous carbonization furnace is the most important part of the production line. During the process, the furnace also shoulders the responsibility of adjusting and monitoring the data of the carbonization furnace. Only in this way, can the equipment maintain the stability of the process and the quality of the final products. In addition, as an automatic device, it achieves continuous production to improve efficiency and reduce the interference of people.

After the preprocessing, the raw materials get into the continuous carbonization furnace through the inlet of the machine. The inner liner has a transmission gear ring, which drives the inner liner to rotate. It makes the heat more uniform. At the stage of endothermic pyrolysis at 150-300℃, the raw material begins to decompose and release gaseous products. The pyrolysis temperature of different materials is different, and the temperature of materials with low transformation is also lower. The temperature in the carbonization stage is 300-600℃. The main reaction is thermal decomposition. The capacity of the machine is about 500kg/h. Take the coconut shell as an example, materials containing less than 10% per ton can obtain 280kg-310kg final products.

At the end of the process, the water cooling system helps to reduce the temperature of the final product. The cooling water flowing in the shell carries the discharge carbon heat away. Finally, the final products get through the outlet to complete the entire conveying and cooling process.

What development trend does the carbonization furnace catch?

After years of development, the continuous carbonization furnace owns the knowledge of the frontiers. With a reasonable design and operation, the machine can maintain the safety and stability of the process and bring out the best performance of the machine.

What is the price range of the continuous carbonization furnace?

Since the continuous furnace has a wide application, the price range of the machine can be wide. The normal price range of the machine is between $5,000 to $50,000. The huge difference in the different machines requires the customers to have a better understanding of their businesses so that the customers can choose the suitable machine at a reasonable price.

Sunrise Machinery Company puts a lot work in the developing and researching of the charcoal-making equipment. With years of experiences of making machines, the company has the ability to provide the best user experience for the customers. Since the information of the machine is extremely easy to obtain, if you would like to learn more about the machine and production line, please leave your message here, the professional service staff is going to get to you as soon as possible.