As a traditional smoking style, hookah takes up an important position in Middle Eastern culture. For that reason, the consumption of hookah charcoal is a great opportunity to grab. What’s more, the raw materials of hookah charcoal are normally wood, bamboo, coconut shells, or other plant materials. With more and more people starting to realize the potential of biomass, the technology of producing hookah charcoal is going through rapid development. The hookah charcoal production line is a great answer to increase the productivity of the hookah charcoal and earn more profits.

How do the Raw Materials Turn into Hookah Charcoal?

In order to realize the conversion from biomass materials to hookah, people should have a basic idea of the working theory of the transformation. For the start, the raw biomass materials get into the converting environment. When the container meets the standards of carbonization, the covert begins. Organic substances at high temperatures, due to the lack of oxygen, can not be completely burned, will occur pyrolysis reaction, decomposition into carbonaceous products. The carbonization furnace in the charcoal production line is where the pyrolysis happens. The hookah charcoal line adopts the most advanced technology and most green energy sources. Since hookah charcoal can directly contact the users, the requirements for hookah charcoal are stricter. A set of qualified and guaranteed hookah charcoal machines is necessary to start the business.

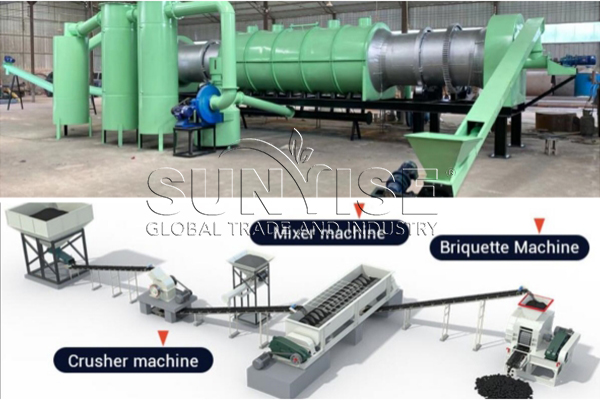

What Machines does the Hookah Charcoal Production Line Need?

The component machines in the hookah charcoal production line are important. The machine set can be customized and decided by the customers. However, there are three machines that are necessary for the whole process.

How to Improve the Quality of the Hookah Charcoal?

Three main machines can set up a basic charcoal production line. However, with the development of technology, customers have started to have a higher demand for the final charcoal products. Besides the basic equipment, there are other methods that can improve the quality of the hookah charcoal.

Raw Material Optimization

Select raw materials with good quality and stable performance to ensure stable product quality. It can optimize the ratio of raw materials and improve the performance and market competitiveness of products. The smoke of the hookah charcoal can directly contact people, so it is necessary to adopt better raw materials to promote the quality.

Equipment Upgrade

Update and improve the production equipment, introduce new efficient and energy-saving equipment and technology and improve the operation efficiency and stability of the hookah charcoal production line. The easiest change in the charcoal production line is the integration and automation. With a higher level of integration and automation, the process can be finished with a higher working efficiency.

Process Optimization

The production process of hookah carbon was optimized to improve production efficiency and product quality. The optimization still needs the assistance of the production machine, so it is important to choose a trustworthy charcoal machine manufacturer to provide sincere help and professional advice to optimize the process. Sunrise Machinery Company has a good reputation among customers due to its customer service. Feel free to contact us, and get started on your business.

What is the Price Range of the Hookah Charcoal Production Line?

Standard

- For a Perfect Small-scle

- Hookah Charcoal Production Line

- Perfect Products, professional manufacturer

With all the information above, you may be interested in starting your own hookah charcoal business and earning profits in this traditional cultural custom. The budget for starting a charcoal production line is the concern that the customers care about the most. Normally, the budget for a small-scale hookah charcoal is between $20,000-$50,000. Of course, the prices have a huge difference due to the different requirements. The price range is only a reference for the customers. If you would like to learn the specific price or the detailed arrangement, please feel free to contact us.

Since Sunrise Machinery Company has its source factory, the machine line can be designed according to the customer’s requirements. The offer of the company can be the most reasonable price in the market. Sunrise Machinery is a machine manufacturer that the customers should not ignore. The professional and careful service can prove the company takes highly on the customers’ experience. Please feel free to contact us, our customer service staff will answer you as soon as possible. If you would like to learn more about the hookah charcoal production line or charcoal-making machines, please call us or send an E-mail to get more information.