In order to follow the trend of clean energy, people start to realize the importance of the exploration of green and renewable. Biomass charcoal is a newly thriving energy production industry, and the outcome of the production line can have many applications. The final charcoal products can be used in many different fields to meet different requirements. Therefore, the customers should have a clear consideration of the factory to choose the most appropriate machine line on a limited budget. What if the budget is limited to $50,000, how to use the money to purchase the most suitable machine set to start the business?

What machines are necessary in the charcoal production line?

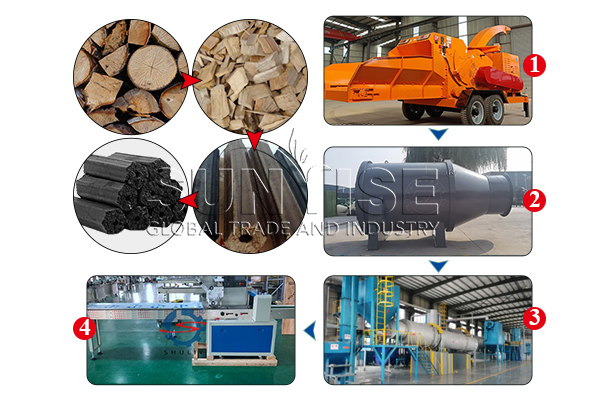

In order to realize the transformation of raw materials to charcoal products, the production line needs to contain several necessary machines to perform. During charcoal production, the machines should assist in the transformation of the raw materials.

Cutting machine

The first step of charcoal production is to reshape the biomass sources. Since most raw materials are usually hard and irregular, to ease further procedures, the uniform shape or powder status can improve the working efficiency of the carbonization. The most common crusher machine in the charcoal production line is the double shaft shredder machine. The equipment employs two rollers with blades so that the rotation can tear the materials apart. The double shaft shredder machine is famous for its strong tearing power. The price between $2,000-$10,000 has competitiveness in the market.

Industrial dryer machine

Moisture is a problem that many people usually tend to forget. During the carbonization process, the moisture may cause the low-speed of the working efficiency and damage to the machine. The industrial dryer machine is a good tool to resolve this problem. The equipment adopts a high temperature to remove the moisture. More treatment for the raw materials and higher quality does the final products contain.

Carbonization furnace

After the special treatment, the raw materials are ready to get into the carbonization furnace. The carbonizing furnace creates a confined place for the biomass materials to convert. The environment with less oxygen and higher temperatures can accelerate the working efficiency of the transformation process. In order to satisfy large-scale business owners and small-scale business owners, there are several types of carbonization furnaces for customers to choose from. The hoisting carbonization furnace and the horizontal carbonization furnace are perfect for small-scale businesses. As for the larger scale factory, the continuous carbonization furnace can provide better help.

What other machines can improve the quality of the charcoal products?

How to choose the suitable machines for your business?

In order to select the most suitable machine line for production, there are three aspects that the producers would consider the most.

Capacity

For the industrial production, the capacity is the first thing that the customer should consider. Sunrise Machinery Company has many different capacity machine assemblies to satisfy the different needs of the customers. Both small-scale and large-scale business owners can find their ideal set in Sunrise.

Raw materials

Most charcoal producers choose biomass materials as the raw materials of the charcoal products, so the sources of biomass charcoal can be various. The machine line should be set to easily process the raw materials. Sunrise Machinery Company has special solutions for different raw materials. With years of experience to contact with that customers, the company can provide the most suitable solution.

Price

The price of the machine set is something that every customer pays more attention to. Sunrise Machinery Company, as a long-lasting machine supplier, the company owns a source factory. Without the middleman between suppliers and customers, the price is the most reasonable. If you would like to purchase the charcoal production machine line, Sunrise Machinery Company is a choice that you should not ignore.

Charcoal Production Line

What is the price of the charcoal production machine?

Sunrise Machinery Company has a good reputation among its customers. The professional advice and the careful customer service help the company win the prefer of the customers. If you are interested in purchasing the charcoal production set, Sunrise is an option that you should not miss. Please feel free to contact us, our customer will answer your question as soon as possible.