The electronic automobile is now becoming a normal item in our daily lives. With the quick increase in the utilization of the lithium battery, the disposing treatment is something that the industry should care about. The lithium battery recycling system is designed by the machine manufacturers to meet the needs of the market. What’s more, the machine line can not only reduce the pollution of the lithium battery but also rejuvenate the value of the waste materials. The lithium battery recycling line is a developing investment that could bring more profits for the owners.

The Process of the Lithium Battery Recycling

In order to set up a functional and suitable lithium battery recycling line, there are three phases that are important in the machine line. Due to the special features of the lithium battery, the machines should have unique treatments for the materials in different procedures.

Pre-process

Before the disposal treatment, the lithium battery needs to discharge the electricity. It is an important step for the pre-treatment of the lithium battery recycling line. The waste lithium battery still contains a certain amount of electricity. If the unprocessed waste batteries get into the shredding or crushing process, the battery may short circuit, heat, and even cause fire or explosion and other safety accidents. To remove the electricity in the batteries, the waste can be soaked into brine, which can reduce the electricity in the battery to less than 1 volt. As for the inert gas method, the electricity still remains in the batteries. However, the content of the oxygen is lower than 2% to decrease the risk of explosion. Therefore, the waste lithium battery needs to go through preparation to conduct further processes.

During Recycling

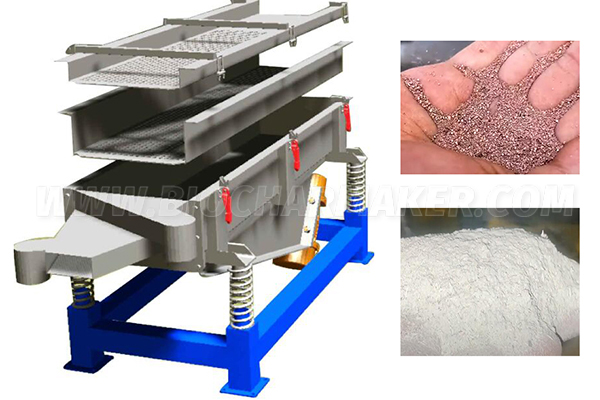

The first step that the materials need to go through is shredding. In this step, the shredding machine tears the waste materials apart. Then, the debris gets into low low-temperature drying oven to evaporate electrolytes to completely avoid the risk of explosion. After the evaporation, the conveyor belt transports the materials into the crushing machine and sorting machine. All the materials that have not completely decomposed get to the collector, and go through several rounds of crushing and sorting machines. In the end, the materials are separated into copper powder, aluminum powder, diaphragm, and other materials. In order to process more detailed classification, there are several kinds of sorting machines in the recycling line. The magnetic sorting machine can separate the metal powder from other materials, and the gravity sorting machine can classify copper and aluminum. Hence, the lithium battery recycling line can collect all the useful materials to earn more profits.

To set up the waste lithium battery recycling line, there are several necessary machines that need to be considered. In the normal circumstance, the price range of the recycling line is between $100,000-$300,000. Due to the huge investment, a trustworthy machine manufacturer is necessary. Sunrise Machinery Company has its source factory, so the price can be the most reasonable in the market. The recycling machine line can be customized according to the requirements of the customers. If you would like to learn more about the e-waste recycling line, please feel free to contact us. Our customer service staff can provide you with the most professional advice and most caring service. We are looking forward to your reply.