The Charcoal Shaping Machine in South Africa

For years of running the Sunrise Machine Company, we have received many types of requirements from many places. This successful case is from South Africa. With years of experience dealing with the requirements of the customers, our customer service staff is now good at providing advice to the customers.

For a long time, our company can receive inquires form a lot of places. South Africa is a place that has a lot of potential customers. One of the customers has reached out to us to inquire for more information about the charcoal briquette-making machine. During the discussion, many thoughts and ideas come out of both sides. It is a great example of presenting professional knowledge and a caring attitude to the customers. Our customer service staff showed the best performance.

Preparation of the Case

In the first e-mail, the customer did not talk about the project too much. The customer only told us what kind of machine he wanted, which required our customer service staff to follow for more information and details. In the following communication, the customer offered more specific requirements for the machine, which requires more sturdy status with the assistance of a hydraulic system. After the decision of the charcoal briquette-making machine, the discussion went into the next phase.

During the Discussion

In order to realize the best performance, the customer has strict standards for the machine. There are many different kinds of charcoal briquette-making machines to form the charcoal powder into the charcoal briquettes. The most common machines are the extruder machine, rotary press machine, and the roller press machine. All these machines have their unique traits to cope with different needs.

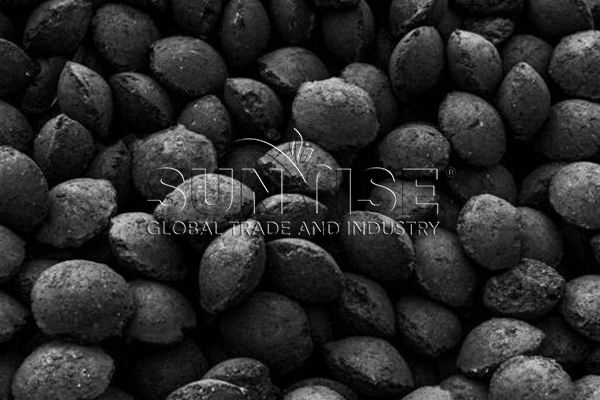

The extruder machine can convert the charcoal powder into the charcoal rod. What’s more, the machine can also process the debris of raw materials into more regular shapes to ease the process. The rotary press machine adopts the hydraulic system to form the charcoal balls. Due to the high-speed rotation, the capacity of the rotary press machine is the highest of the forming machines. As for the roller press machine, two rolling shafts compress the charcoal powder together to form the charcoal balls. Compared to the rotary machine, the roller press machine can deal with small-scale production at a lower price. At last, the customer chooses the roller press machine.

Agree on the Details

When everything is already set and done, the next thing that should be taken into consideration is the price. Most machines set the price range between $1,000-$5,000. The customer chose the type of $3,000, which is more suitable for the charcoal production plant. After agreeing on the deal, our specialized staff then shoulder the responsibility of installing the machine and providing professional operational teaching and advice. In addition, our machine comes with a one-year warranty. We can provide words and video teaching to resolve the problem that the operator may have to encounter.

Sunrise Machinery Company is a machine manufacturer with years of experience of making charcoal production machines. The customer was satisfied with the customer service and the quality of the machines. The charcoal production machine can be customized according to the requirements of the customers. If you are interested in our charcoal production machines, please feel free to contact us. Our customer service staff can provide you with detailed information and professional assistance. We are looking forward to your reply.