How does the Continuous Carbonization Furnaces work?

The continuous carbonization furnace shoulders the responsibility of the transformation of the raw materials. The working principle of a continuous carbonization furnace helps the raw materials to convert. Therefore, this article will discuss about the continuous carbonization furnace.

Continuous carbonization furnace are a crucial component of the charcoal production process, enabling the conversion of biomass materials into high-quality charcoal efficiently and effectively. These furnaces operate continuously, allowing for a steady production flow and consistent output of charcoal. In this article, we will explore how continuous carbonization furnaces work, highlighting their key components, operation processes, and benefits.

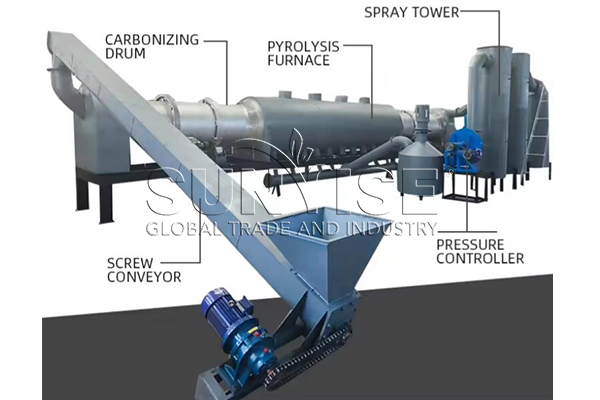

Key Components of Continuous Carbonization Furnaces

Continuous carbonization furnaces are typically comprised of several key components that work together to convert biomass materials into charcoal. These components include a feeding system, a carbonization chamber, a heating system, and an exhaust system. The feeding system is responsible for introducing raw biomass materials, such as wood or sawdust, into the carbonization chamber. Once inside the chamber, the biomass undergoes a controlled heating process, facilitated by the heating system, which raises the temperature to around 500-800 degrees Celsius. This high temperature triggers a series of chemical reactions that transform the biomass into charcoal. The exhaust system then removes excess moisture and volatile gases produced during the carbonization process, ensuring a high-quality final product.

Operation Process of Continuous Carbonization Furnaces

The operation of a continuous carbonization furnace begins with the feeding system loading raw biomass materials into the carbonization chamber. As the biomass moves through the chamber, it is gradually heated to the desired temperature, initiating the carbonization process. During this process, volatile compounds in the biomass are released as gases, which are then captured and used as energy sources to sustain the heating of the chamber. The remaining solid material is transformed into charcoal, which is continuously discharged from the furnace as the production cycle progresses. This continuous operation allows for a steady flow of charcoal production, with minimal downtime and high efficiency.

Benefits of Continuous Carbonization Furnaces

Continuous carbonizing furnaces offer a range of benefits that make them a preferred choice for charcoal production operations. One key advantage is their high efficiency, as they enable a continuous and automated production process that maximizes output and minimizes labor requirements. Additionally, continuous carbonization furnaces are designed to optimize energy use, with the heat generated during the carbonization process being recycled to sustain the heating of the chamber. This energy-efficient design not only reduces operating costs but also minimizes environmental impact by lowering carbon emissions. Furthermore, continuous carbonization furnaces produce high-quality charcoal with consistent properties, making them ideal for commercial use in various industries, such as metallurgy, agriculture, and energy production.

In conclusion, continuous carbonization furnaces play a vital role in the charcoal production process, offering a reliable and efficient method for converting biomass materials into charcoal. By understanding the key components, operation processes, and benefits of continuous carbonization furnaces, charcoal producers can optimize their production operations and achieve high-quality charcoal output. With their automated and energy-efficient design, continuous carbonizing machines are a sustainable and cost-effective solution for meeting the growing demand for charcoal in various markets.

As a machine supplier with a good reputation, Sunrise Machinery Company is a perfect machine manufacturer for beginners in the industry. The company has contact with the customers for a long time, so we can provide professional advice and caring service. If you are interested in our charcoal production line and machines, please feel free to contact us. Our professional customer service staff can provide more information for you.