How does the Lithium Battery Recycling Machine Line Work?

With the thriving development of electronic technology, the disposal of electronic devices is something that the industry should figure out a method to deal with the problem. The lithium battery recycling machine line is one of the disposal methods used to rejuvenate the value of waste materials.

Preparation of the Recycling Line

For the recycle of lithium battery, there are several steps that the operators need to pay more attention. The first thing for dealing with the lithium battery is to go through the electricity discharge. There are two methods to remove the electricity. One is to soak the battery into the brine, and the other is to use the inert gas, such as nitrogen to keep the battery in a stable status. The oxygen content can be lower that 2%, which can highly prevent the explosion. When the preparation is done, the batteries are going to the first shredder machine. After the first shredding, the size of the materials can reach to 4cm x 10cm. However, when the second shredding end, the size can narrow to 2cm x 3-4cm. At present, the battery materials are ready to get into the Low temperature drying oven.

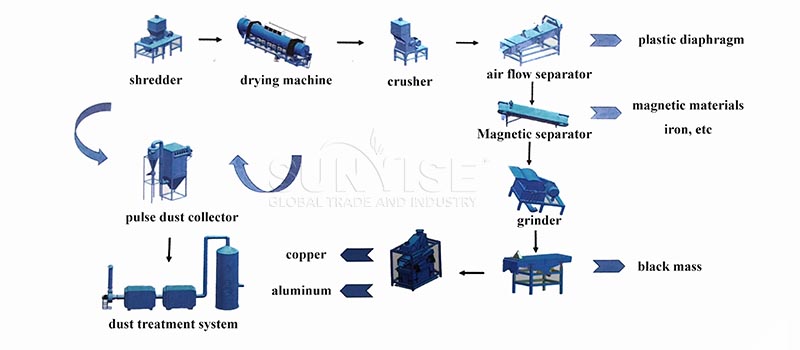

The Working Process of the Lithium Battery Recycling Line

Although the furnace is called Low low-temperature drying oven, the temperature still can reach to 90-120℃. This machine accelerates the evaporation of electrolytes to lower the risk of detonation. During the drying process, waste air and organic matter are produced. The wastes need to use specific equipment to deal with. Then, the materials need to cool down until the temperature is lower than 60℃. The water transport screw conveyor can transport the materials into the next machine. What’s more, the screw conveyor adopts a two-layer system. The recycling water fills in the gap between the two layers to lower the temperature.

The Collection of the Recycling Line

In order to separate copper powder and aluminum powder, the materials need to go through several times of grind and separation. With the help of draught fans, magnetic separator, and drum plug, the size of the copper powder and aluminum powder can achieve 30-140 mesh. Other materials, such as diaphragm and carbon black, can also be produced by processing lines. The lithium battery recycling machine line has no waste outcomes. Therefore, the lithium battery recycling line is a very promising industry to attempt.

Sunrise Machinery Company is a machine manufacturer with rich experience. With the source factory, the company can offer you the most reasonable price in the market. If you would like to learn more about lithium battery recycling, please feel free to contact us. The professional customer service staff can answer you with detailed information and parameters. We are looking forward to your reply.