As a harmless and environmentally friendly fuel, many industries use it as a burning material. The hookah charcoal production line of Sunrise Machinery Company uses its automatic machines and technological processes to maintain the high quality of the final products. People pay more attention to production due to the enhancement of environmental concepts. With the mass demand from the market, the biomass charcoal production line owns a sound development in the future.

What is a hookah charcoal production line?

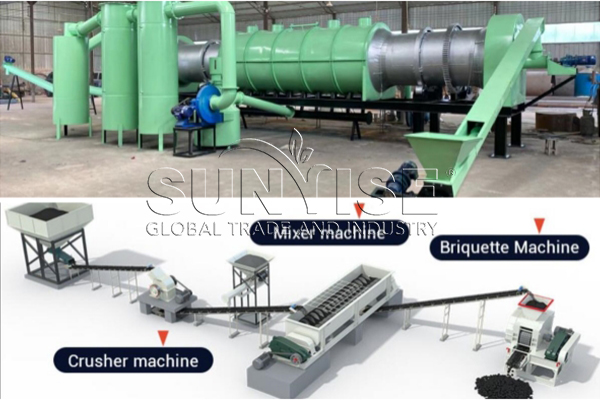

The hookah charcoal machine line specializes in the production of hookah charcoal and mainly includes the preparation of the raw materials, carbonization, grinding, pressing, and packing. The final products of the machine line can have direct contact with people, so most producers choose biomass or agricultural wastes as the raw material to avoid the risk of exposure to toxic substances. As a result of the growing demand for environment-friendly products, hookah charcoal slightly enters the scene.

The hookah charcoal line takes biomass materials and agricultural waste materials as feedstock, and the recycling of the wastes is good for environmental protection and energy saving. The design and structure of the hookah charcoal machine line aim to increase the working efficiency and reduce the cost. In the meantime, the quality and stability of final products are also guaranteed. Therefore, most machines in the hookah charcoal production line are using automatic control to regulate the products.

What raw materials can form the hookah charcoal?

For the hookah charcoal has to contact people directly, the raw materials need to go through a thorough examination to make sure the final product causes no harm even after burning. All these limitations narrow the choice of biomass wastes and agricultural wastes. The safety and operability make the materials solid choices.

Agricultural Wastes

The biomass materials here are usually referring to the plants. Wood and bamboo are the two most common options for hookah charcoal-making. Many industries utilize these two materials as basements, but the waste and byproducts have the same properties without enough attention. In addition, the conversion to charcoal can arouse the potential of the materials. As a result, business owners can obtain the same quality materials at a lower price to save the cost.

Biomass Materials

During agricultural processing, it is inevitable that the grains leave the waste parts to improve the quality. The waste materials are the perfect choice for charcoal-making. No matter whether it is the rice husk, coconut kernel shell, or straw, the charcoal production line can bring out the best performance of the materials. The wide choice of raw materials gives business owners a chance to use different materials at different times to achieve the maximum sustainable revenue.

What equipment is used in hookah charcoal production line?

Besides suitable material election, it is also necessary to buy professional equipment for shisha biochar making line. Because it is the secret of finishing hookah charcoal smoothly and quickly. But what machine is needed for hookah charcoal production? In general, you need the following three shisha charcoal processing machines.

What advantages does Sunrise’s hookah production charcoal line contain?

As a manufacturer with rich experience, Sunrise has a great knowledge of what customers would look for while purchasing the production line. By the time of the machine-producing process, the company would pay extra attention to the details that the customers would focus on. Careful thinking has become the advantage of the shisha charcoal production line.

Improve Efficiency

The hookah carbon production line uses automatic equipment and machines for production. Thereupon, the adoption greatly improves production efficiency and saves human resources and time costs. The techniques of the machines allow the working process non-stop. The high efficiency can bring more profits to the business owners.

Ensure Product Quality

In order to meet the customer needs, the hookah charcoal processing line maintains product quality stability and consistency through strict process flow and quality control measures. The hookah production line sets a reasonable production process according to the characteristics of the product, and through strict control and monitoring, to ensure that each final product meets the standard requirements.

Reduce Production Costs

Through technical methods, the adoption of automation equipment and intelligent control can assist in reducing labor and time costs. The hookah carbon production line has to form large-scale production to ensure the quantity of output. In the meantime, a large amount of material handling offsets the losses in carbonization, and improves the competitiveness of enterprises.

What benefits of the hookah charcoal production line of Sunrise Company can bring to the business owners?

As a charcoal production line, being functional and profitable are the basic requirements. What’s more important is how much benefit can the production line bring to the business owners. In recent years, the demand for green energy has gotten higher and higher, so the clear economic efficiency of the products is good for the development of the business.

Brand Promoting

As the last step of the production line, the packing machine not only plays the character of protecting the final products but also adds more value to the final products. Since the automatic production can regulate the basin parameters of the final products and the packing bag has the brand of the factory, the customers of the hookah charcoal will have an impression of the products. If the quality of the products leaves a good impression on the customer, the reputation of the brand can be beneficial for the business.

Lower Labor Cost

For the high efficiency of the production line, most owners would choose automatic machines to finish the production line. The utilization of machines also means the reduction of the labor cost. Precise control and continuous working precede the labor work. With the fully automation production line, the operation only needs several workers to finish.

How to further process hooksh charcoal to get more profits?

If you want to get more profits from hookah charcoal, we recommend you convert shisha biochar into briquettes. And there are some machines for your choice.

What is the price of the hookah charcoal production machine line?

The price of hookah charcoal production line is an item you must focus on. Then what is the quote for a hookah charcoal making line? In general, this production system needs $10,000-$50,000 (reference price). But It is not fixed, because it is closely related to the materials types and capacity. The less the materials types and the smaller the capacity, the lower the cost. If you want to get a more precise quote of the hookah charcoal system you need, you can contact us immediately. We will offer you customized project design and corresponding quotation.

Sunrise Machinery Company has years of experience in manufacturing the machine line. With a high reputation, the company is trustworthy. If the customers are new to the business, the manufacturer can provide them with professional help and design. If you would like to learn more about the machine and production line, please leave a message. The professional staff will bring more details and parameters for you to choose from.