To realize the protection of the environment, the researchers of charcoal products started to look for a raw material that is renewable and eco-friendly. As an agricultural waste, straw has a sustainable and vast supply. The straw pellets machine line is where the straw materials turn into the charcoal pellet. For the most important part of the production line, the carbonization furnace creates a suitable environment for the carbonization process of the straw. Since straw is an accessible resource, it is the perfect material to become charcoal. For economy efficiency, the performance of the straw can satisfy the requirements of the business owners.

What is a straw pellets machine line?

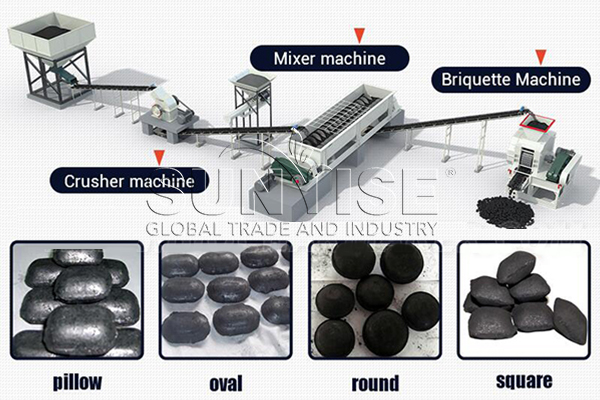

The straw pellet-making line takes straw as the raw material for charcoal pellets. The main purpose of this set of machines is to convert agricultural waste into charcoal pellets to add more value to it. To ensure the performance of the whole process, high-quality machines are something necessary. The cutter machine, the dryer machine, the carbonization furnace, the grinding machine, the briquette machine, and the packing machine form the line of charcoal processing. The combination of the machines brings the whole and perfect carbonization performance to the straw materials.

With the assistance of the machines, the straw can rejuvenate its value. As an agricultural waste, the reuse of it is a good way to save energy and protect the environment. The charcoal pellets machine line transforms the waste into useful biomass, reducing pollution and waste. The final product is a renewable resource. With the features of environmental, automatic, and efficient, the machine line occupies an important application value in the disposal and utilization of biomass materials.

How does the straw convert into a charcoal pellet?

For the straw materials to become charcoal pellets, there are several steps that the raw material needs to go through. The straw charcoal briquette machine line can use the most suitable machines to complete the process. The customization of the charcoal production line is common for the machine manufacturers, so the machine line can make the most of it according to the requests of the customers.

Why use straw as the raw material?

Renewable resource

Due to the raw material being agricultural waste, the supply of the straw is sustainable and stable. Straw is the generic term for stems of many crops, which means the materials can be harvested according to the seasons. During grain processing, the farmer usually collects the grain and disposes the straw. Since the straw charcoal pellet machine line can use the straw as the working material, the carbonization process for the straw is a better solution.

How can the straw pellets machine line create economic efficiency for the owner?

The final destination of the machine line is to earn more profits and to realize that goal, the raw materials are one the most important factors that can affect the profits. The reason why the straw can bring economic efficiency to the business owner is the following aspects.

Therefore, the choice of straw as a carbonization raw material can meet the market demand and obtain better economic benefits.

What is the budget range of the straw pellets machine line?

The price range of the straw charcoal-making line can be wide. For the basic equipment of the production line, the budget range of the line is between $20,000-$50,000. As for the large-scale production line, the price can be over $100,000. The price can change with the requirements of the customers. The customization of the production line may add more cost to the production line. Therefore, the customer should have a better understanding of the machine to pick the most suitable one.

However, if the customer is new to this industry, a reliable manufacturer is the most important factor that the customer needs to consider. Sunrise Machinery company is an experienced producer with a high reputation. Their years of experience allow them can design the factory and provide high-quality machines for the customer. Please leave a message if you would like to learn more about the machine and production line.