With the thriving development of electric cars and electronic equipment, the treatment of the lithium battery is something that needs to pay more attention to. More and more people are starting to innovate new methods to recycle the lithium battery through research and development. The lithium battery recycling machine line of Sunrise Machinery Company contains the most advanced equipment to collect useful materials. Due to the increasing number of electronic equipment, e-waste recycling is now coming into sight and becoming an extremely promising industry.

What is a Lithium Battery Recycling Machine Line?

The lithium battery Recycling Machine Line is a recycling line for the waste lithium battery. The main purpose of this machine line is to effectively extract and recycle useful materials in used lithium batteries. According to this move, the recycling line can not only reduce pollution to the environment and save energy consumption but also bring more economic benefits to the owners. The lithium battery recycling line assists in addressing the urgent task of how to deal with obsolete electronic equipment.

The appearance of the lithium battery recycling machine line follows the trend of development of the lithium battery. The amount of the waste lithium battery gets increased by the thriving status of the electronic equipment. The recycling line is meant to collect copper powder, aluminum powder, and carbon black to earn more profits. Sunrise Machinery Company, as a machine manufacturer, has rich experience in machine production. The company enjoys a good reputation for the quality of the machines. The customers can have faith to trust the company.

What Composes the Lithium Battery Recycling Machine Line?

Unlike other production, lithium battery recycling has a higher standard for pretreatment. In order to improve the purity of the outcomes, the quality of the machines is necessary. There are several machines that are necessary for the lithium battery recycling.

How does the Recycling Line Work?

To deal with the waste lithium batteries, the first thing that the operator should to is to discharge the electricity of the batteries. According to the brine or the nitrogen, these methods can remove the electricity in the batteries to lower the risk of detonation. Then the batteries should be under the blazing sun for quite a long time and move to the shredding machine. When the materials get into smaller pieces, the operator can choose different methods to recycle materials.

Low Temperature Drying

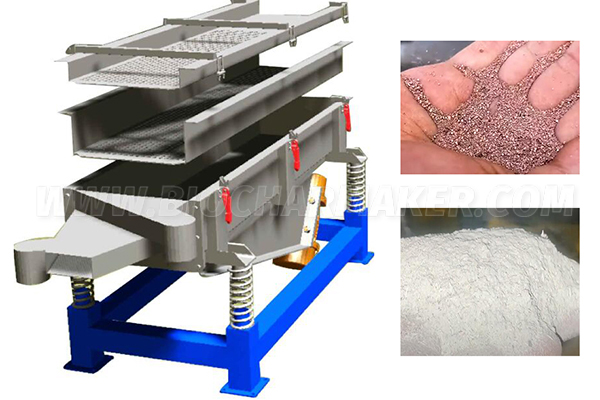

In this method, the debris of the waste lithium battery gets into the low-temperature drying machine. The furnace removes the moisture in the materials. Next, the shredding machine comes into sight and breaks the materials into smaller sizes. With the assistance of linear machines and sorting machines, the classification of the outcomes can be guaranteed.

High Temperature Pyrolysis

As for the high-temperature pyrolysis, the operator should use the pyrolysis furnace to heat it up to a high temperature. In the high-temperature environment, most parts of the lithium get to carbonize. It is easier for the machine line to separate the metal powder and carbon black. Different customers may have different outcome requirements for the machine line. Sunrise Machinery Company can provide these two kinds of machines to meet different needs.

How does the Lithium Battery Recycling Machine Line Bring Economic Benefits?

For the thriving utilization of the lithium battery, the recycling and treatment of this green energy should be put on the agenda. Despite the number of waste lithium battery, the future of reuse the materials is promising.

Resource Reuse

Lithium batteries contain limited resources, such as cobalt, nickel, manganese, and other metal materials, through the recycling production line extracting and recycling these valuable metals, can save a lot of resources, and reduce the demand for natural resources. If the waste lithium battery is not handled properly, it may cause pollution and harm to the environment, and the recycling and processing of the waste lithium battery through the recycling production line can reduce the negative impact on the environment and reduce the pressure of waste disposal.

Promote Circular Economy

The lithium battery recycling production line realizes the transformation of waste resources to valuable resources, and realizes the circular economy model of waste reuse, which is conducive to improving the efficiency of resource utilization and reducing resource consumption.

What is the Price Range of the Recycling Line?

With all the information above, people would like to learn more about the lithium battery recycling machine line. The price range is one thing that the customer is interest in the most. In the normal circumstance, the price range is between $80,000-400,000. The customer can choose the machine set that fits their factory conditions.

Sunrise Machinery Company is famous for its quality and enjoys a good reputation among its customers. With the source factory, the company can offer the customers different machine lines. Therefore, if you are interested in the recycling line of the lithium battery, please feel free to contact us. Our customer service staff can offer you the most reasonable price and the most professional information and advice. We are looking forward to your reply.