What is the price range of hookah charcoal production line?

When it comes to the thriving of renewable energy, biomass charcoal is a topic that people cannot ignore. The wide range of applications ensures a promising future for charcoal production. The hookah charcoal production line is one of the examples that can present the diversity of charcoal usage.

The market demand of hookah charcoal brings out the production line. In order to seize the opportunity, machine manufacturers have started to innovate better charcoal production lines to produce hookah charcoal. Unlike the other kinds of charcoal products, hookah charcoal has direct contact with people, so the standards of hookah charcoal production are higher than the normal charcoal line. The price range of the hookah charcoal line can be wide due to the customers’ different requirements. Therefore, business owners should select a trustworthy manufacturer to support the business.

The Production Process of the Hookah Charcoal

Preparation

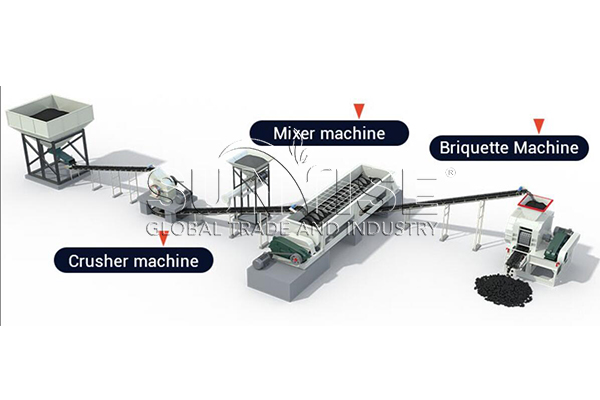

In order to bring out the best quality of the hookah charcoal, the performance of the machines is extremely important. Since the hookah charcoal should be smokeless, odorless, and have a long burning time, the most common raw materials of the hookah charcoal are the coconut shells. A strong crusher machine is necessary to crush down coconut shells. The double-shaft shredder machine adopts two main rollers to tear the materials apart. Normally, the price range of the shredder machine is between $3,000-$5,000. Then, the material debris should get into the dryer machine to remove the moisture. Because the moisture may slow down the working efficiency and cause damage to the carbonization furnace. The drying process is necessary. The budget for the dryer machine is between $3,000-$5,000.

Carbonization

When the raw materials are ready to get into the carbonization furnace, the most important part of the charcoal production line has started. The carbonization furnace creates a high-temperature and oxygen-deficiency environment to accelerate the conversion. According to different demands for the capacity, Sunrise Company can provide you with different types of carbonizing furnaces. For the small-scale production line, the hanging carbonization furnace is perfect, and the continuous carbonization furnace is the perfect equipment for large-scale production.

Forming Process

After the carbonization, the reshaping of the charcoal products is also necessary. The milling machine can help the charcoal bulk get into charcoal powder to conduct further treatment. The smaller particles can improve the delicacy of the final products. The shaping machine is an important part of the whole shaping line. Most charcoal briquette machines adopt the hydraulic system to achieve the compression of the charcoal balls. The molds of the shaping machine can alter the shapes of the final charcoal products. At the end of the charcoal production line, a unique packing bag of charcoal products is important as well, for it is the first impression for the customers.

Sunrise Machinery Company

Sunrise Machinery Company is a machine manufacturer with years of experience in producing charcoal-making machines and charcoal production lines. What’s more, the company has a source factory, so the company can provide the machines as the customers require. In addition, with the source factory, the company can offer the customers the most reasonable price. The Company can provide you with the most professional and careful service for the customers. Sunrise Machinery Company puts a lot of effort into the customer’s experience.